Air ducts are one of the easiest places for mold to become a “whole-house” problem, because they sit at the intersection of three things mold likes: hidden surfaces, dust (food source), and intermittent moisture from humidity, condensation, or HVAC performance issues. When mold in air ducts shows up, it’s rarely confined to a single corner the way a visible bathroom spot might be. A moldy HVAC system can move air through multiple rooms every day, which means whatever is inside the ductwork can keep circulating.

It’s also why air duct contamination often gets missed early. Many homeowners notice a pattern first: the house smells “off,” the air feels stale, or irritation seems worse when the system runs, even when there’s no obvious mold on walls or ceilings. That doesn’t automatically prove mold in HVAC ducting, but it does explain why symptoms and odors frequently lead the story long before anyone sees anything. If you’re experiencing persistent musty smells or poor air quality, learn more about how to eliminate mold odors and improve your indoor air quality.

This guide is designed to make the situation clear and practical: how to recognize what’s actually happening, how to think about risk without panic, what approaches work (and what doesn’t), and when duct cleaning alone isn’t enough because the real driver is moisture, not dirt.

What Is Mold in Air Ducts?

Mold in air ducts refers to active microbial growth inside HVAC ductwork or connected components, most often on the interior duct surfaces, within the air handler cabinet, on duct liner/insulation, or near areas where moisture collects.

It’s not the same thing as “dirty ducts.” Ducts can be dusty for years without mold. Mold becomes a real issue when moisture and organic debris come together and allow colonies to develop.

Two duct zones matter:

- Return ducts pull air back to the system. Because returns move large volumes of air, they tend to collect more organic dust (skin cells, pet dander, textile fibers, paper/cellulose particles). That buildup can become a food source if it gets damp.

- Supply ducts push conditioned air out to rooms. Supply-side mold is more likely when there’s condensation, wet insulation, or moisture introduced near the coil/plenum area.

Mold may not be visible at vents even when it’s present deeper in the system. Growth often forms:

- further upstream from registers,

- on the underside of duct surfaces,

- inside the air handler, around the coil compartment, or within a return plenum,

- on a duct liner where it’s hidden behind a grille.

A key distinction: dust contamination vs. active growth. Dark residue on a vent can be ordinary dust, soot, or airflow “ghosting” patterns. Active microbial growth is more likely when there’s evidence of persistent dampness, irregular spotting/smearing that returns after cleaning, or visible growth on interior materials, especially insulation or areas that stay wet.

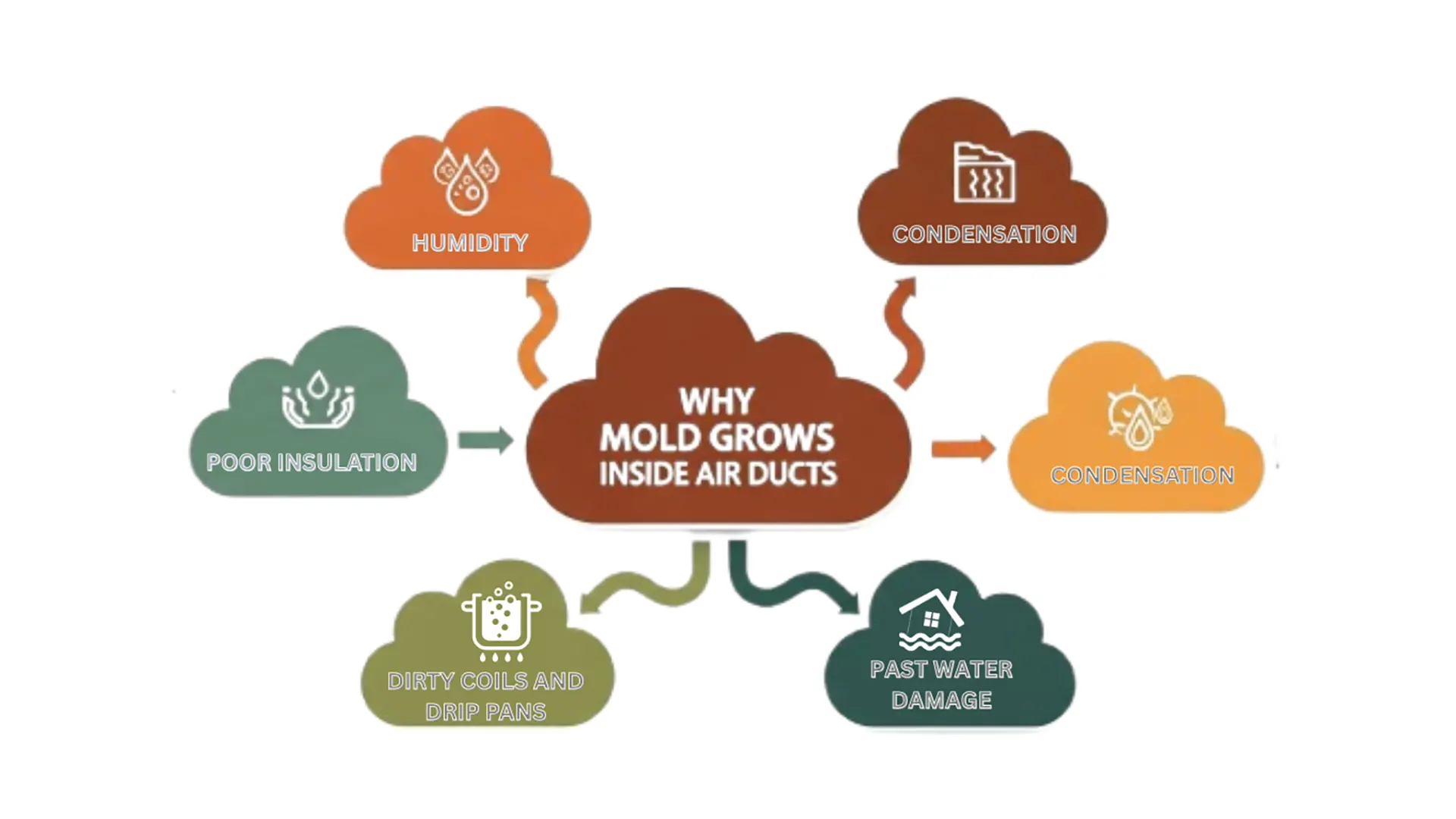

Why Mold Grows Inside Air Ducts

Mold growth in HVAC systems is driven by a simple rule: no moisture, no sustained growth. Ductwork is naturally dark and often dusty, but those conditions alone don’t create mold. The tipping point is usually moisture in air ducts, and the most common HVAC-related moisture mechanism is condensation in HVAC components and nearby duct sections.

Here’s how that moisture gets introduced and sustained:

Humidity + Condensation Inside Ducts (Primary Driver)

When warm, humid air meets cold surfaces, especially during air conditioning, water can condense. The cooling process also removes humidity at the coil, which produces water that must drain correctly. If moisture persists, it can wet dust and insulation and create a stable environment for microbial growth. Learn more about managing humidity levels in your home.

Poor Insulation or “Sweating” Ductwork

Ducts running through attics, crawlspaces, or other unconditioned areas can “sweat” when insulation is missing, compressed, or damaged. Cold supply ducts are particularly prone to surface condensation when surrounding air is humid.

Past Water Damage or Flooding

If a home has had a leak, roof intrusion, flooding, or a wet crawlspace, duct insulation or duct liner can stay damp long after the visible water is gone. Porous materials hold moisture and can support recurring growth.

Dirty Coils and Drip Pans

Coils, drain lines, and drip pans are designed to handle water. When they’re dirty or partially clogged, water can overflow, pool, or aerosolize, increasing humidity inside the cabinet and nearby duct areas. Dust + moisture in these spots can accelerate microbial buildup.

In short: mold growth causes in HVAC setups almost always trace back to repeated wetting events, not just “old ducts.”

Signs of Mold in Air Ducts

With duct-related mold, the most reliable early clues are usually patterns, (especially changes that track with HVAC operation) rather than a single symptom or one dirty vent. Separate what you notice into sensory cues, physical indicators, and whole-home patterns.

Odor and Air Quality Signs

- Musty smell when the system turns on, especially after it’s been off for a while

- Odor is strongest near vents or in rooms closest to the air handler

- Smell fades or disappears when HVAC is off, then returns with operation

- Air feels “damp,” “stale,” or “basement-like” specifically during cooling cycles

Visual and Physical Clues

- Dust that reappears quickly after cleaning (not proof of mold, but a sign something is being redistributed)

- Dark residue on vents or registers (can be ordinary dust/soot, but worth attention if it returns fast or looks blotchy)

- Visible growth near the air handler, inside the coil cabinet, around the return plenum, or on nearby insulation

- Evidence of moisture: wet insulation, water staining, slime/biofilm in the drain pan, or recurring dampness around the unit

Home Pattern Indicators

- Multiple rooms affected rather than one isolated area

- The smell or “stale air” issue is repeatable and predictable (e.g., same time of day, same cycle behavior)

- Repeated cleaning or filter changes don’t resolve it, even though the house looks clean

- Comfort complaints seem tied to time spent indoors and HVAC runtime (this is a pattern to note, not a diagnosis)

Health Risks of Mold in Air Ducts

The health concern with mold in air ducts isn’t just that growth exists, it’s that HVAC operation can distribute airborne particles repeatedly. When air moves across contaminated surfaces or disturbed dust, it can carry a mix of:

- mold spores

- tiny mold fragments

- dust and allergens bound to that contamination

- and odors associated with microbial activity

Exposure Mechanics: Why Ducts Can Amplify Impact

Duct systems can turn localized growth into a repeated exposure route because air is cycled throughout the home. Each heating/cooling cycle can reintroduce particles, especially if contamination is near high-airflow zones (returns, blower compartment, coil cabinet, or the first stretches of supply duct).

Dose and Duration Matter More Than Scary Labels

Risk is strongly influenced by how much contamination is present and how long exposure continues. A brief odor event doesn’t equal a major hazard. Ongoing growth combined with frequent HVAC runtime can create a higher “dose over time,” which is when people are more likely to notice effects. Understanding how quickly mold can grow helps explain why prompt action matters.

This is also why focusing only on “toxic mold” labels is often unhelpful. The practical driver is persistent moisture + ongoing distribution, regardless of the specific mold name.

Common, Non-Diagnostic Effects People Report

Without trying to diagnose anyone, the most common issues associated with mold exposure are:

- respiratory and sinus irritation (stuffy nose, sneezing, throat irritation)

- asthma and allergy exacerbation (wheezing, coughing, increased inhaler use in known asthmatics)

- headaches, fatigue, or brain fog can occur, but these are non-specific and can have many causes, so they should be interpreted cautiously and in context.

Higher-Risk Groups (clearer stakes)

Some people are simply more vulnerable to indoor air contaminants:

- Children

- Older adults

- People with asthma or known environmental allergies

- Immunocompromised individuals (for example, those undergoing certain medical treatments or with conditions that reduce immune function)

If symptoms are persistent or worsening, it’s reasonable to treat that as a signal to evaluate the environment and involve a clinician, rather than self-diagnosing based on duct appearance alone.

Can Air Duct Cleaning Remove Mold?

Yes, sometimes. Air duct cleaning can remove mold if the situation is primarily loose contamination (dust and debris that’s carrying mold spores) or very limited surface growth in accessible sections, and the contractor uses proper measures, like containment and HEPA collection so material isn’t redistributed.

But in many real-world cases, standard duct cleaning fails to solve “mold in air ducts” because the problem isn’t just dirt. It’s ongoing moisture + active growth, often in places a basic cleaning doesn’t fully reach (coil cabinet, blower compartment, drain pan area, porous duct liner, wet insulation, or deeper trunk lines).

Dust Removal vs. Microbial Remediation (Maintenance vs. Corrective Work)

- Duct cleaning (maintenance) is primarily about removing dust and debris from duct interiors and registers to improve cleanliness and airflow.

- HVAC mold removal / remediation (corrective) is about addressing active microbial growth and the conditions allowing it, especially moisture, and ensuring contamination isn’t being continuously reintroduced.

If active growth is present, treating it like a “cleaning job” is often why it comes back.

Why Surface Cleaning Alone Often Fails

Surface-only approaches can miss the root drivers:

- Moisture remains (condensation, sweating ducts, high indoor humidity, wet insulation, drainage issues)

- Growth may be on porous materials (duct liner, fiberglass insulation) where scrubbing or vacuuming doesn’t fully remove embedded colonies

- The most contaminated areas may be upstream (coil/plenum, air handler cabinet) and continue to seed the system after the ducts are cleaned

So the ducts look better, but the system keeps producing the same odor and air-quality pattern.

Risk of Spreading Spores During Improper Cleaning

Improper “blow-and-go” cleaning can make things worse:

- Agitation without containment can aerosolize particles

- Lack of negative pressure / HEPA collection can push debris into rooms

- Contamination can be dislodged and redistributed to cleaner duct sections

This is one reason people sometimes report that the smell or irritation seems worse right after a poor-quality duct cleaning.

When Antimicrobial Treatments May (Or May Not) Help

Antimicrobial sprays, fogging, or “sanitizers” are often marketed as a shortcut. They can be useful only in narrow cases, such as:

- small amounts of growth on non-porous, cleanable surfaces, after physical removal

- as a supplemental step once moisture is controlled and the system is properly cleaned

They often don’t help (or are over-sold) when:

- there’s wet insulation/liner or porous materials involved

- active growth is being fueled by ongoing condensation

- the application is used instead of physical removal (killing isn’t the same as removing)

Bottom line: if you’re asking “does duct cleaning remove mold,” the honest answer is it can reduce contamination, but it doesn’t reliably solve active mold unless it’s paired with moisture correction and, when needed, true remediation steps.

How Mold in Air Ducts Is Properly Addressed

A professional approach treats duct mold as a moisture-driven contamination problem, not a cosmetic issue. The steps below reflect what “properly addressed” typically looks like when the goal is long-term resolution.

1) Inspection of Ducts and Air Handler (Not Just Vents)

- Visual inspection of supply and return trunks, accessible runs, registers, and boots

- Inspection of the air handler cabinet, coil compartment, blower housing, and nearby insulation

- Checking areas where growth commonly hides (plenum transitions, liner seams, low spots) For a comprehensive mold inspection checklist, visit our detailed guide.

2) Moisture Source Identification (Non-Negotiable)

This is the make-or-break step. The contractor should identify why moisture is present, such as:

- condensation issues at the coil/plenum

- sweating ducts from poor insulation

- drain pan/drain line problems

- duct leakage pulling in humid air

- short-cycling or airflow restrictions affecting dehumidification

If the moisture cause isn’t found and corrected, cleaning becomes a temporary reset.

3) Containment and HEPA Filtration

Before disturbing contamination, pros typically use:

- negative pressure collection at the duct system

- HEPA-filtered air scrubbers in the work zone when needed

- controlled access openings and sealing to prevent debris blowback

The goal is to remove material without redistributing it through the home.

4) Physical Removal or Targeted Duct Replacement (When Needed)

- Mechanical removal (HEPA vacuuming + controlled agitation) for dust and removable growth

- If mold is in porous duct liner/insulation or the material is water-damaged, replacement of affected sections may be the most reliable solution (because porous materials can stay contaminated even after surface cleaning)

5) Cleaning Coils, Pans, and Blower (Often the Real Source)

A lot of “duct mold” problems persist because the contamination is actually concentrated around:

- evaporator coil

- drip pan and drain line

- blower housing and cabinet surfaces

Cleaning these components is often required to stop re-seeding the ducts.

6) Moisture Correction: Insulation, Drainage, Airflow

The final step is fixing the conditions that allowed growth:

- improve duct insulation where sweating occurs

- correct drainage slope/clogs; verify pan and drain line function

- seal duct leaks and improve return pathways

- address system sizing/balancing issues that contribute to high humidity or poor dehumidification

If you want, I can write the next “Decision” section that helps readers choose between: monitor/DIY humidity control, schedule professional inspection, or escalate to remediation/replacement, without fear tactics. Our professional mold remediation services can help address HVAC mold issues effectively.

Testing for Mold in Air Ducts

Testing can be useful, but it’s important to treat it as confirmation and documentation, not the primary way most homeowners “discover” a duct problem. In many cases, the first actionable step isn’t a lab result. It identifies where moisture is entering the system and whether there’s evidence of active growth in the air handler, coil area, or duct materials.

When Testing Makes Sense:

Testing is most helpful when you need to:

- Confirm whether suspicious material is microbial growth versus ordinary dust/soot

- Document conditions before/after work (insurance, landlord/tenant, contractor scope)

- Guide next steps when inspection findings are unclear or disputed

- Support post-remediation verification (PRV) after professional remediation

Testing tends to be less helpful when it’s used as a substitute for inspection or moisture diagnosis. A sample can’t explain why the conditions exist, and without that, even “good” results don’t prevent recurrence.

Air Sampling vs. Surface Sampling

Air sampling measures what’s floating in the air at a specific time and place. It can provide a snapshot of airborne particles, but it’s highly variable based on HVAC runtime, weather, room activity, and sampling location. Air samples can be useful for comparing areas (e.g., supply air vs. indoor air vs. outdoors), but they are not a guaranteed indicator of what’s inside ductwork.

Surface sampling (swabs, tape lifts) targets visible residue and can help identify whether what you’re seeing is consistent with microbial growth. This is often more direct when there’s suspicious material on a vent, inside the air handler cabinet, or near the coil/plenum area. Still, it only tells you what’s on that specific sampled spot, not what’s happening elsewhere.

Why Negative Tests Don’t Always Mean “No Problem”

A negative or low-result test doesn’t automatically close the case. Reasons include:

- Mold can be localized deep in the system, and the sample location missed it

- Airborne levels can fluctuate (the “dose” changes with runtime and disturbance)

- Recent cleaning, filter changes, or low HVAC use can reduce what’s captured

- Growth can exist on porous liner/insulation where surface sampling is inconsistent

That’s why testing is best framed as supporting evidence, not the single deciding factor.

Post-remediation Verification (PRV)

After remediation, PRV is about confirming that:

- contaminated materials were removed or replaced where needed

- HVAC components were cleaned appropriately

- moisture conditions were corrected enough to prevent recurrence

- the system isn’t redistributing contamination

PRV may include a visual re-inspection, moisture checks, and sometimes targeted sampling, used thoughtfully, not automatically.

Preventing Mold From Returning to Air Ducts

Prevention isn’t about finding the perfect spray. It’s about controlling the environment that allows mold to persist, especially moisture and dust loading inside the HVAC system. If those drivers are controlled, recurrence becomes much less likely.

Humidity Management

- Keep indoor humidity in a stable range (many homes aim for about 30–50%, adjusting for climate and season)

- Reduce sources of indoor moisture (unvented showers, cooking without exhaust, wet basements/crawlspaces)

- Use dehumidification when needed, especially in humid climates or shoulder seasons

Proper Duct Insulation

- Insulate ducts in attics/crawlspaces to reduce sweating

- Repair crushed, missing, or wet insulation

- Address duct sections that repeatedly show condensation or staining

Regular HVAC Maintenance

- Maintain coils, drain pans, and drain lines so water drains correctly and doesn’t pool

- Replace filters on schedule and use filters appropriate for the system (over-restrictive filters can create airflow problems)

- Make sure condensate management is working during peak cooling months

Correct System Sizing and Airflow

- Avoid short-cycling issues that cool without effectively dehumidifying

- Ensure returns aren’t undersized or blocked and supply airflow is balanced

- Seal duct leaks that pull in humid attic/crawlspace air

Prompt repair of leaks or flooding

- Dry wet building materials quickly after leaks

- Inspect HVAC and nearby ductwork after any water event, especially if ducts run through basements, crawlspaces, or low areas

- Replace water-damaged porous duct materials rather than “treating” them

When to Call a Professional for Mold in Air Ducts

Many duct concerns can start with basic steps (filter change, checking obvious condensation, improving ventilation). But when patterns persist, or when there’s evidence that contamination is being distributed, professional evaluation is a reasonable next step. Think of it as moving from “maintenance” to “diagnosis and correction.”

Call-out indicators that escalation makes sense

- Persistent musty odor despite cleaning and normal housekeeping

- Symptoms that seem tied to HVAC operation (worse when running, better when away), especially if multiple people notice it

- Visible growth inside ductwork, inside the air handler cabinet, near the coil compartment, or on insulation

- A known history of water damage or flooding, especially if ductwork or HVAC components were exposed to moisture

A good professional visit should focus on finding the moisture driver, inspecting the air handler and duct materials, and explaining whether the situation looks like dust contamination, active growth, or a component-level issue (coil/pan/blower) that’s seeding the system.

Mold in Air Ducts: Final Thoughts

Mold in air ducts is easy to underestimate because it’s often hidden and the earliest clues tend to be patterns, odor when the system runs, recurring residue, multiple rooms affected, not a dramatic visible patch. The real risk isn’t just that mold exists somewhere; it’s that HVAC airflow can reintroduce contamination repeatedly throughout the building.

If there’s one principle that keeps this from becoming a cycle, it’s this: cleaning without moisture control doesn’t last. Long-term resolution comes from identifying why moisture is present, correcting it, and then cleaning or replacing affected materials in a contained, methodical way.

If you want help thinking through what your signs point to, the most productive next step is a professional inspection focused on moisture and HVAC components, not just vent cleaning. And if our team serves your area, we can evaluate what’s happening and recommend the least invasive option that actually prevents recurrence.

Frequently Asked Questions About Mold in Air Ducts

How is mold different from just “dirty ducts”?

Dust alone is not mold; mold requires moisture plus organic debris to grow, while ducts can stay dusty for years without microbial growth if they remain dry.

Can mold be present even if I don’t see anything on the vents?

Yes, growth often hides deeper in trunk lines, plenums, or on insulation inside the air handler, so vents can look normal while contamination sits upstream in the system.

Why does mold grow inside HVAC ducts?

Mold growth in ducts almost always traces back to repeated moisture events like condensation on cold metal, wet duct insulation, or drainage issues around the coil and pan.

What are the most common moisture sources in HVAC ducts?

The most common moisture sources in air ducts include high indoor humidity, sweating ducts in unconditioned spaces, past water damage that left materials damp, and clogged or poorly sloped condensate pans and drain lines.

What are the most common signs of mold in air ducts?

Homeowners often notice musty odors when the HVAC turns on, stale or “damp” air during cooling cycles, recurring dust or dark residue at vents, and issues affecting multiple rooms rather than a single corner.

Why does my house smell musty only when the AC or heat runs?

When the system starts, air passes over contaminated surfaces and carries odor-causing particles into rooms; when the unit is off, that circulation stops and the smell often fades.

What health effects are associated with mold in air ducts?

Mold exposure can cause stuffy nose, coughing, wheezing, sore throat, and eye or skin irritation, and may worsen asthma or allergies in people who are already sensitive.

Who is at higher risk from mold-contaminated HVAC systems?

Children, older adults, people with asthma or environmental allergies, and those who are immunocompromised or have chronic lung disease are more vulnerable to indoor mold exposure.

Does the specific mold species (like “black mold”) matter most?

For most homes, total exposure over time and ongoing moisture conditions are more important than the species name, since many indoor molds can trigger similar respiratory or allergic effects.

Can standard air duct cleaning remove mold?

Duct cleaning can remove loose dust and some surface contamination, but it rarely solves an active mold problem unless moisture sources and contaminated components like coils and pans are also addressed.

When is mold remediation needed instead of just cleaning?

If growth is visible, recurring, or present on porous materials such as duct liner or fiberglass insulation, guidance from EPA and industry standards is to remediate and often replace affected materials rather than just clean them.

Are antimicrobial sprays or foggers enough on their own?

No, killing organisms without removing contaminated material and fixing moisture does not provide durable results and is not a substitute for proper cleaning and source control.

Do I need mold testing to know if ducts are a problem?

Not always; visual findings, moisture evidence, and consistent odor or symptom patterns tied to HVAC operation are often enough to justify corrective work without extensive lab testing.

What’s the difference between air sampling and surface sampling?

Air samples capture particles at one moment in time and can fluctuate widely, while surface samples focus on specific residues and are better at confirming if visible material is consistent with mold.

Can a “negative” test mean there’s still a problem?

Yes, samples can miss localized growth, and recent cleaning or low HVAC use can reduce airborne counts even when contamination remains inside ducts or on insulation.

How can I prevent mold from returning to my air ducts?

Keeping indoor humidity in a reasonable range, maintaining condensate drainage, insulating ducts in attics or crawlspaces, sealing duct leaks, and changing filters on schedule all reduce the conditions mold needs to regrow.

What humidity level should I aim for indoors?

Many agencies suggest maintaining indoor relative humidity roughly between 30% and 50% and avoiding chronic dampness, adjusting for climate and season.